How to Problem Solve Leachate and Landfill Gas Issues Using Data Management Tools

The Advantages of Real-Time Data in the Landfill Industry

This article is based on a presentation by Laura Williams of Sanborn Head & Associates. Sanborn Head works in partnership with ddms, Inc. to implement data management solutions for the landfill industry.

Being in the landfill industry has never been simple, and it’s only getting more complicated.

“We see multiple challenges, from increasing volumes and types of waste, to continually changing regulations, to the inherent challenges of collection and containment,” said Laura Williams of Sanborn Head & Associates, an engineering and technical consulting firm serving clients in the development, energy, industrial, and solid waste markets. “Then add to that the risk of managing the byproducts of landfills including gas and leachate.”

As an example of just one harmful gas, US municipal solid waste landfills are the third- largest source of methane — a climate pollutant with 80 times more warming power than carbon dioxide in the short term.

The first step to managing gas and leachate in landfills is to understand volumes, types, and locations. That’s a challenge in and of itself. Think of traditional data collection like trying to understand a book by reading a few words at a time, days or weeks apart. That gives you a sense of how hard it can be to get useful information when it’s based on critical data collected manually during periodic site visits.

The solution? Using advanced telemetry for data collection (without site visits) combined with data management systems that provide real-time data acquisition, analysis, and control. With those tools in place through SCADA (supervisory control and data acquisition) systems, landfill operators can accurately and efficiently monitor and analyze data.

This real-time access, through systems like ddms’ Project Portal®, allows landfill operators to make informed business decisions and proactively mitigate risk. (ddms is a consulting firm providing environmental data management services, analytics, visualization, and enterprise implementation services to a multitude of industries through their team of scientists.)

Beyond Compliance to Competitive Advantage

The consequences of data gaps go beyond regulatory concerns. “When companies can’t see real-time patterns, they’re essentially flying blind, unable to optimize performance or prevent issues from turning into problems,” said Laura Williams of Sanborn Head & Associates, “not to mention that manual data collection is time- consuming and liable to errors.”

Modern telemetry systems used in conjunction with Project Portal collect data continuously from remote sensors — every 5, 10, or 15 minutes — and transmit directly to cloud-based platforms where it can be analyzed, visualized, and acted on in real- time. That capability represents a fundamental shift from reactive to proactive landfill management.

The telemetry stack typically includes SCADA systems, Modbus communication protocols (to transmit data between devices like sensors, controllers, and PLCs and communicate over networks), and Data Acquisition Systems (DAS) that convert physical signals into digital data streams sent as files to ddms. Automated processes prepare, review, and upload the data to Project Portal. That combination delivers a comprehensive monitoring network that operates 24/7, with fewer impacts from weather conditions or site accessibility.

Critical Data Streams: What Gets Monitored

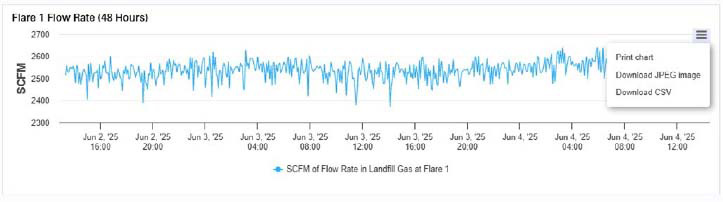

High-Frequency Telemetry Data

Remote sensors capture essential metrics including flow rates, pressure readings, temperature fluctuations, and liquid levels with unprecedented frequency. This high- resolution data provides operators with the granular insights needed to understand operational patterns and identify anomalies before they become problems.

Landfill Gas Wellfield Compliance

For facilities managing a large number of gas wells that require monthly sampling, Project Portal can track methane concentrations, applied vacuum data, and critical temperature thresholds. The platform manages sampling schedules automatically and generates alerts when readings exceed compliance thresholds.

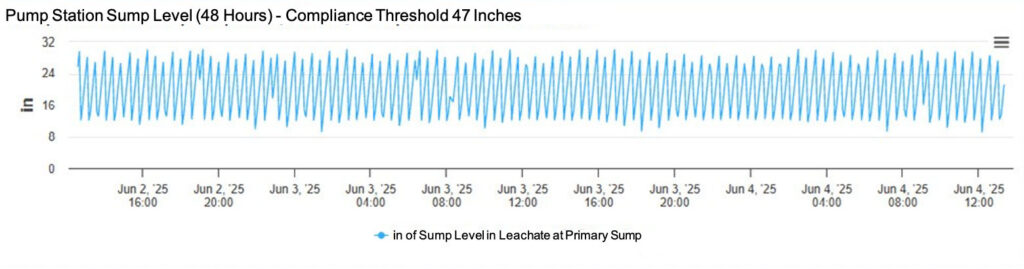

Leachate Management Systems

Real-time monitoring of leachate tank storage levels, sump levels, and flow rates allows operators to detect leakage between containment layers and maintain compliance with level thresholds. Early warning systems prevent storage tank overflows and optimize pump operations.

Example dashboard widget with threshold limit

From Data to Actionable Intelligence

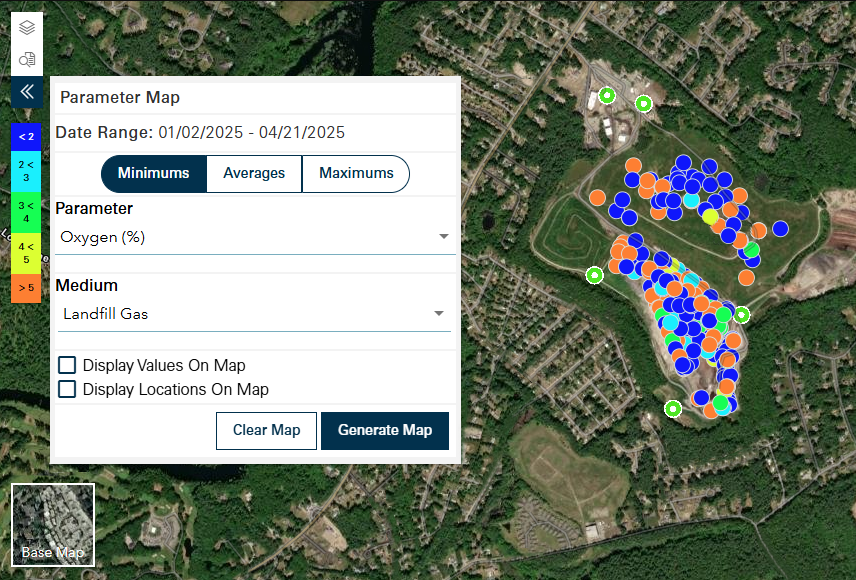

The real power lies not only in collecting the data, but in what to do with it after collection. “As environmental data scientists, we saw the need to create a platform— which we call Project Portal—because we saw the need to take data to the next level, from multiple spreadsheets and charts to dynamic dashboards, GIS mapping tools and automated reports that make complex operational data immediately accessible and actionable,” said Darrick Jensen of ddms, Inc.

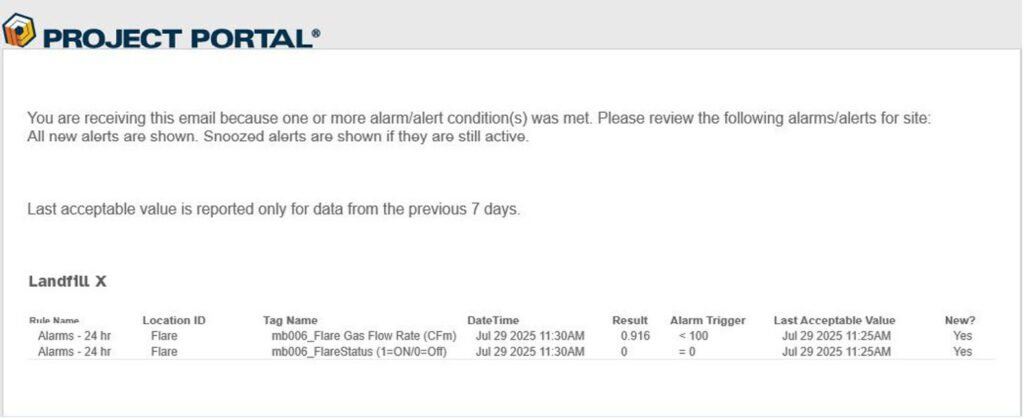

Think of the difference between receiving a weekly report showing average oxygen levels versus getting real-time alerts when oxygen levels indicate a potential vacuum system leak. Real-time alerts make it possible to respond immediately, which means minor issues don’t turn into major operational disruptions.

Benefits of Data Management

The benefits of tools like ddms’ Project Portal extend across multiple operational dimensions:

- Reliable Accuracy and Reduced Costs: Automation significantly reduces manual data collection tasks (like leachate sump compliance), speeds up reaction time, minimizes human error, and frees up technical staff for strategic analysis rather than routine data gathering.

- Improved Safety: Real-time alerts allow operators to address emission anomalies (such as threshold alerts on the oxygen level in landfill gas), equipment malfunctions (like flare downtimes), and compliance concerns before they escalate.

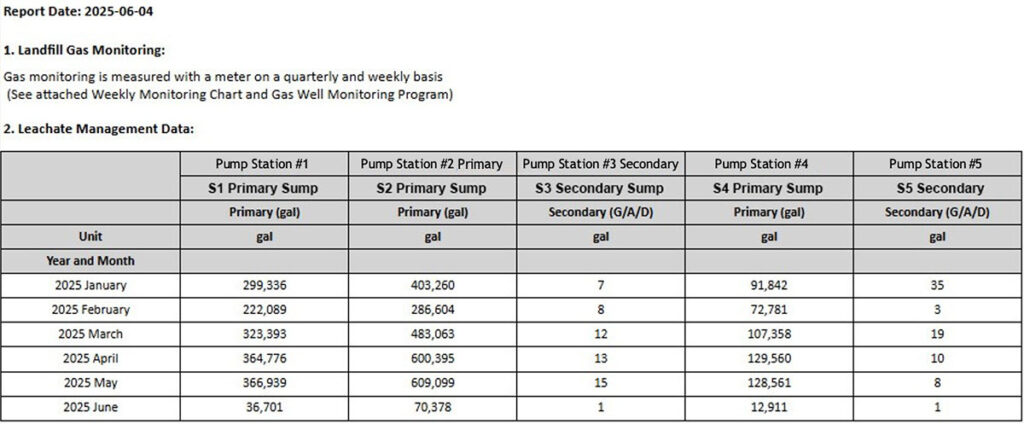

- Streamlined Compliance Reporting: Automated data collection and report generation provide consistent, accurate compliance documentation while reducing the administrative burden. In fact, with customizable dashboards as well as preconfigured options like those available in Project Portal, the reports are easy to create, interpret, and share with a larger group of stakeholders.

- Data-Driven Decision Making: To that point, continuous data streams and shared data make it possible to identify trends, optimize system performance, and make informed decisions based on comprehensive intelligence rather than periodic snapshots.

The Future of Landfill Data Management

The transformation from manual, periodic monitoring to continuous, intelligent data management represents more than a technological upgrade—it’s a fundamental shift toward operational excellence. For landfill operators and industry leaders considering this transition, the question isn’t whether to adopt these technologies, but how quickly they can implement them to stay competitive, compliant and focused on safety in an increasingly complex industry.

The data is clear: real-time monitoring and intelligent data management aren’t just nice- to-have technologies—they’re becoming essential tools for modern landfill operations.

Sample operational report

Sample alert email

Real time map visualization

Map module layers

For more information on how ddms can improve your environmental data program adoption, please email sales@ddmsinc.com